UV Coating Facts:

- Ultraviolet (UV) cure coating is basically a liquid compound when applied over ink to paper and exposed to the correct level of ultraviolet light, becomes instantly solid.

- UV coating does not have any VOCs, so the concern about the inhalation of vapors does not exist. In addition, there are no environmental concerns about hazardous air pollutants because the amount of ozone, produced by the UV lamps due to interaction of UV light and oxygen, is small enough and does not present any issue.

- UV coatings are protective and durable material with high levels of gloss, used in magazines, automotive brochures, annual reports, direct mail and promotional inserts. It is an ideal solution to give magazine covers a shinier, durable, high quality appearance which makes it stand out from the rest.

- UV coating “ adds value to the printed products by making them unique and more eye-catching.“Finishes can range from a flat mat appearance to high-gloss”.

- UV coating can be applied as a flood over an entire web width, or in spots to highlight specific areas.

- UV coating technology is one of the fastest-growing segments in the Graphics Arts industry. In recent years, great technological advances was made in UV equipment and UV inks and coating has led to the safe and widespread acceptance of use of UV curable inks and coating. Today, many printers utilizing UV Curable Coatings on a regular basis to enhance the gloss levels, quality and productivity in both the pressroom and at trade finishing houses.

Performance Advantages of UV Coating:

- Superior Gloss & fast Curing Speed

- Low Energy Costs

- Environmentally Friendly "Zero VOC (Volatile Organic Compounds) Technology "- 100% Solids

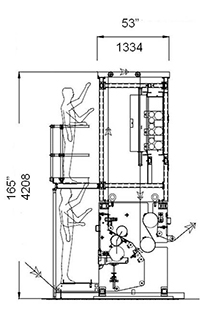

Click to view larger

GWF-Top Side FlexUV Coater

on Rotoman N Press

GWF-Top Side FlexUV Coater

Flex-UV Coater

Introduction:

The GWF Flex-UV Coater is stationary conventional unit, engineered and built for precise lay down of spot or flood UV Coating. The unit is designed to apply high gloss or matte UV finish at high speed on magazine covers, annual reports and unique direct mail pieces. Designed to be installed after the chills unit on the floor or on top of the chills if no space available.

Application:

The GWF Flex-UV Coater incorporates three cylinders design where the anilox or transfer cylinder is immersed in a UV fountain pan. UV liquid is being pumped into the pan via a closed loop circulation pump, the anilox cylinder picks up the UV coated material from the pan, the extra material is skimmed of the surface of the anilox roll via a supplied doctor blade. The metered material is then transferred onto a photopolymer plate mounted on the surface of the plate cylinder, the plate cylinder deposit the UV film on the printed paper.

Key Features:

- Top Side application, full width, single around, stationary.

- Designed to apply a wet coating film to the desired level of gloss

- Designed for full coverage or in-register spot coating within (±.015”) (±.38mm).

- Mechanically designed for maximum press speed of 50,000 iph.

- Integrated chill rolls

- Integrated web tension control system

- Integrated UV curing system

- Extended web lead from point of print to UV curing for longer “Flow Out” time

- CE Compliant

Product Applications:

- Magazine Covers

- Annual reports

- High quality catalogues

- Direct mail pieces

Click to view larger