Model-H.S. Rotary Cutter/

TED Delivery Table

Specifications:

- Designed for maximum web width up to 38” (965mm)

- Designed to cut & deliver 2, 3, 4 & 5 around products of press repeat

- Delivers full bleed trimmed or non-bleed trimmed products.

- Ability to cut and deliver flat full sheet products (see note below)

- Produce straight cut and contour cut products

- Recommended minimum product length possible = 3” (76mm)

- Minimum chip size = .25” (6.35mm)

- Knife To Knife Cut accuracy within .003” (.08m)

- Multiple ribbons thickness cutting capability = .067” (1.7mm)

- Paper Weight, from 35# (51gsm) up to 10pt. (300gsm)

- Maximum speed = 2,000 ft/min. (610m/min.)

Notes:

Production speed can be limited by the type of paper and paper weight especially when paper is light stock as well of speed limitation due to the type of stacker used behind the delivery table. For delivery of flat full sheets, it is recommended to use a silicon applicator prior to the Rotary Cutter

Major Features

Model-H.S. Rotary Cutter/

TED Delivery Table

"Left Hand Design"

Cost Efficient Disposable Knife

Precision Straight Cut

Contour Die Knife

Rotary Cutter:

- Adjustable Entrance Fold Holder

- Entrance motor driven roll with variable speed and texture surface

- Pre-piped grease lubrication system with two centralized manifold

- Double around cylinder cutting couple

- Independent motor driven cutting couple

- Anti-backlash Helical gear cylinder couple in oil bath

- Thermo stabilized cutting couple

- Motorized knife impression adjustment via eccentric on anvil cylinder

- Hardened anvil cylinder with 2/3/4 & 5 up product pinhole configuration

- Knife cylinder with dovetail groove knife block lock-up construction

- Zero Tolerance “ Cutting Edge” Knife Locator Arm

- Disposable knife system with .25” (6.3mm)minimum chip capability

- 8 inch (20cm) diameter waste hood system for chip removal

- Gun bore holes in anvil cylinder to aid in ease of removal of used pins

- ± ¾” (19mm) manual sidelay whole machine

- CE Safety Compliance

T.E.D. Delivery Table:

- Entrance variable speed upper and lower tape accelerator section

- Trailing edge knock Down Wheel with speed selection for 2/3/4 and 5 up products

- Auto Rephrasing TED Knock Down Kicker Wheel

- Variable speed 1st stage full width belt section and lead edge wheel to create product shingle

- Variable speed 2nd stage full width exit belt section with pneumatic up/down & waste removal

- Pneumatic assist roll back delivery table

10" color HMI:

- Remote of all inline/offline operation

- Registration control screens for all tool cylinders

- Precision make-ready knife indexing

- Fault screens with diagnostics aids

- Fixed move (0.0002” per move) knife pressure adjustment

- Draw Rolls (RC draw and inline/offline)

- Variable speed tension control

- Motor load feedback

- Delivery table control

- Variable speeds for all motors

- Auto product knock-down recovery

VPN:

- Remote Internet access to all drive and control systems

- Remote service and diagnostic

- Firmware and software updates

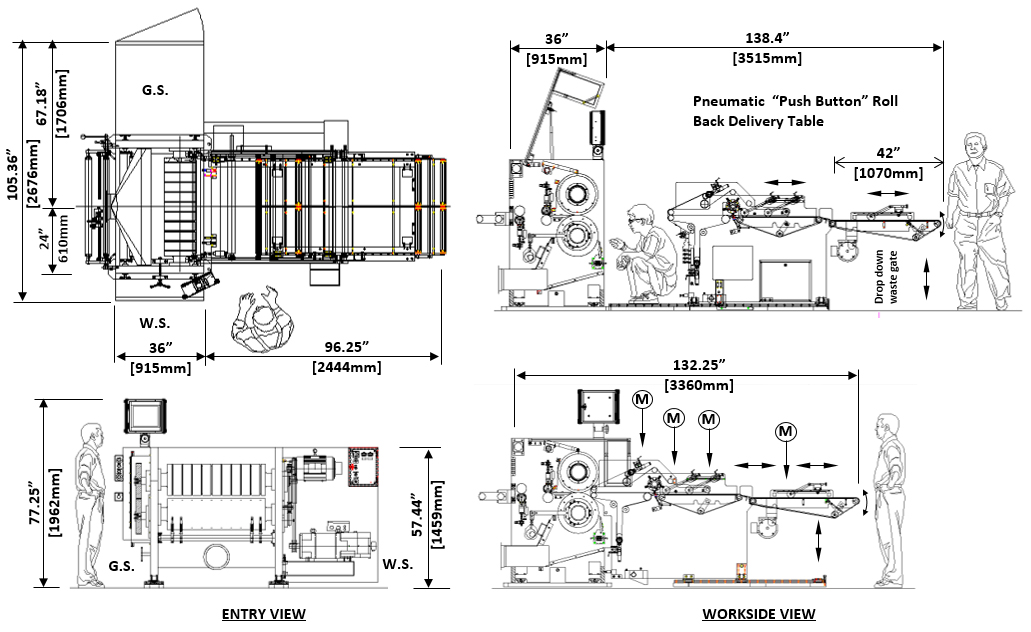

High Speed Variable Rotary Cutter/ with TED

Delivery Table General Arrangement Layout