GWF – U-Shaped Inline Installed

on KBA C16 press

GWF – Portable Bi-level

Plow Towers

Definition:

- In-Line Finishing Condenses the web printing process, the bindery process & the letter shop process into one continuous operation.

- Speed-to-market since there usually are no post-press operations, shipping or mailing can begin soon.

- Depending on the format, 250,000 or more pieces can be most effectively produced in-line.

Application:

- Personalizing

- Gluing

- Coating

- Perforating

- Die Cutting

- Slitting

- Shifting

- Folding

- Cutting

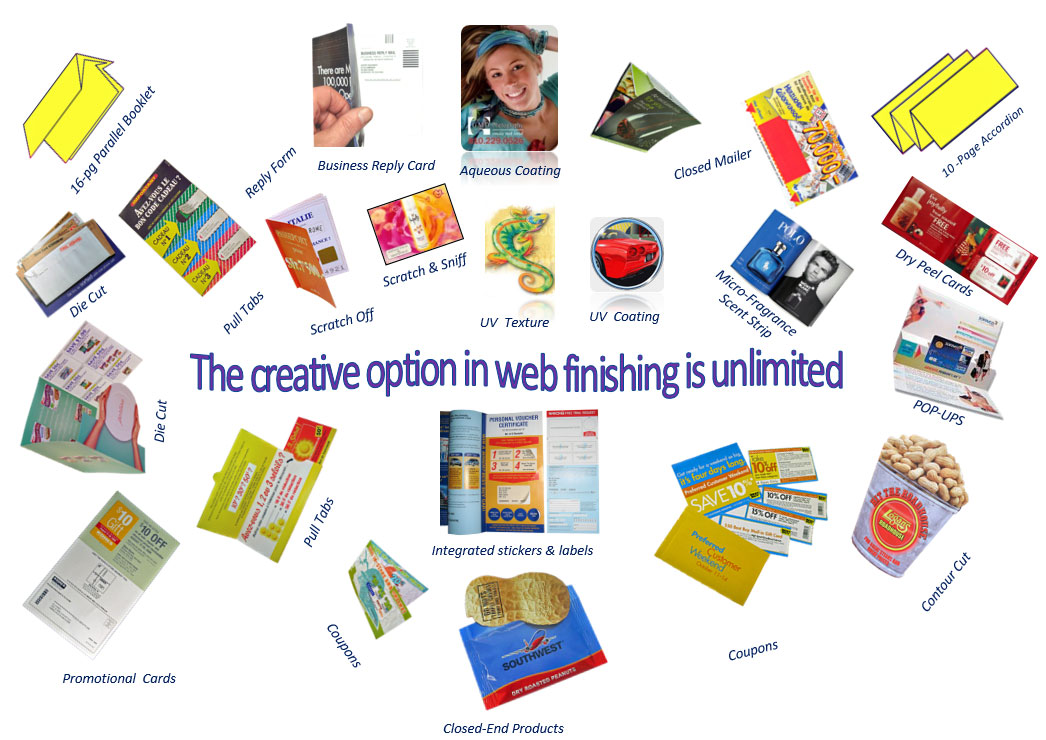

Products:

Limitless type of products can be produced inline with the web press at press speeds up to 1,600 fpm (755mpm):

- 2pg-32pg brochures

- Mini catalogs/ booklets

- Order forms with or without reply envelopes/ cards

- Bankcard applications, nested or non nested letters

- Eye catching products such as Pop-Ups, Pull tabs

- Dry Peel, Integrated label and Stickers

- Scratch & Sniff Inline Perfumed Micro Fragrance Products

- UV & Aqueous Varnish Coated Products

- Security Ink Printed Products

- Promotional Signatures W/ Multiple Shapes Die Cut & Contour Cut

- Personalized Enclosed Mailers W/ Promo Personalized Cards

- Magazine Covers For Saddle Stitching & Perfect Bind

- Diverse Formats of Direct Mail Products

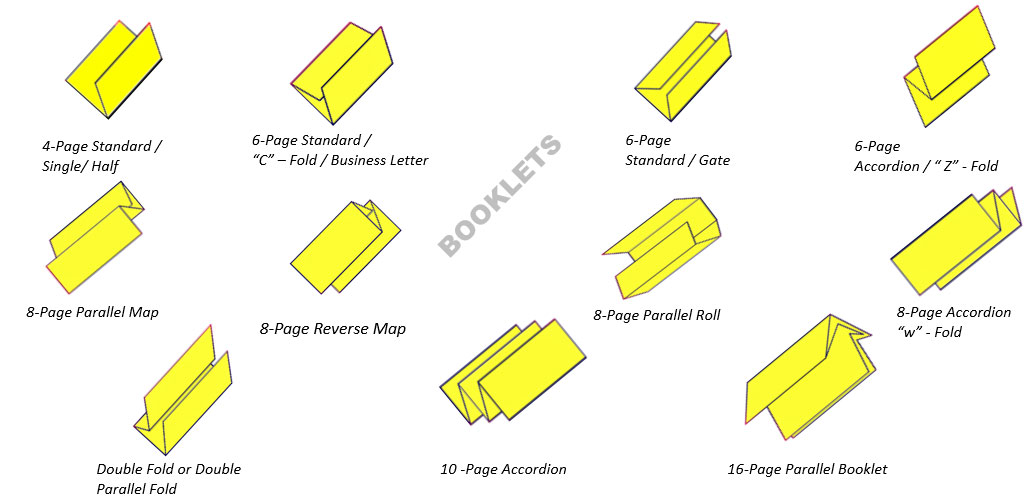

Create Booklet Without Stitching

Many different page counts and sizes of booklets can be produced in-line by spine gluing the pages. These booklets can be standalones, like self-mailers, or can be incorporated into envelope packages. Booklets and folders also can incorporate unique folds and shapes that are difficult to produce in a conventional bindery setting, such as multiple roll folds and Z-folds.